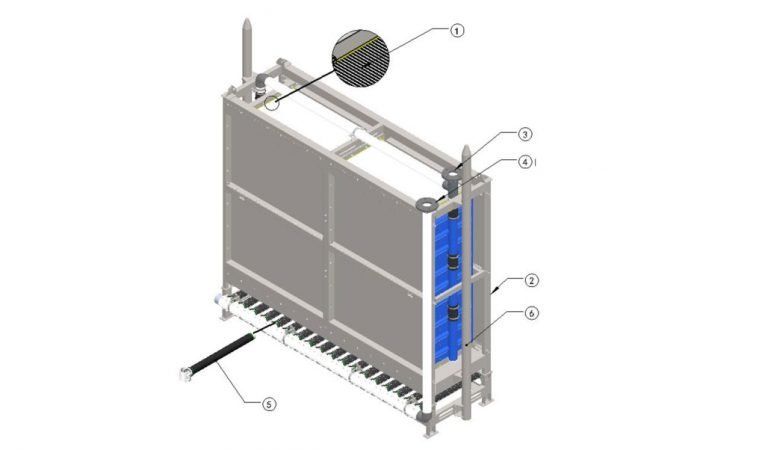

H series MBR membrane systems utilize our braid supported proprietary polyvinylidene fluoride (PVDF) hollow fiber ultrafiltration membrane with a nominal pore size of 0.03. This product is made of strong and durable braided hollow fibers without any breakage (>600N) and high peeling strength. Through high porostity and narrow pore distribution fiber, optimum structure and most advanced syphon aerator design, H series MBR have higher flux, lower fouling rate, longer life time and optimizes the effeciency of air scour which reduce air to permeate ratio (SADp) as low as 3:1 in MBR application.

H series MBR provide widely application and excellent performance to save the cost.