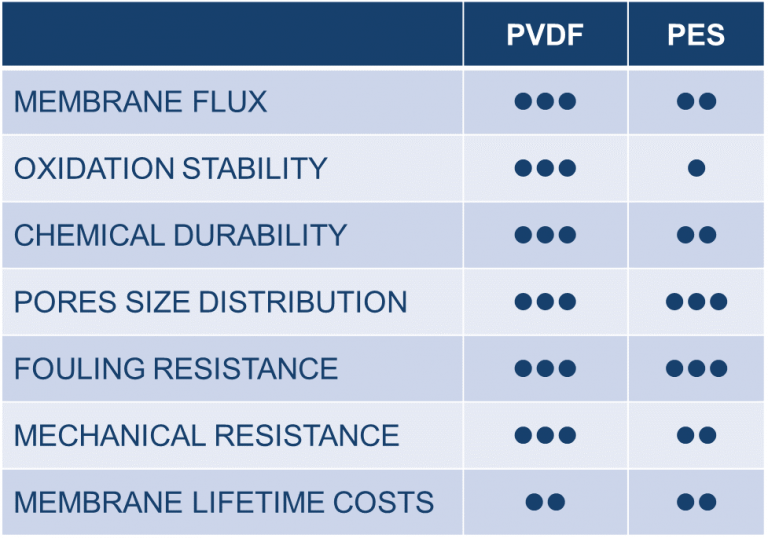

Comparison PVDF vs. PES Membranes

PVDF (Polyvinylidefluoride) and PES (Polyethersulfon) membranes are the most widely used membrane materials for MBR applications.

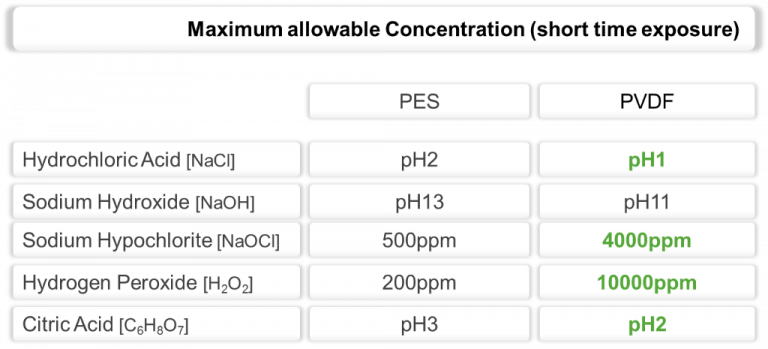

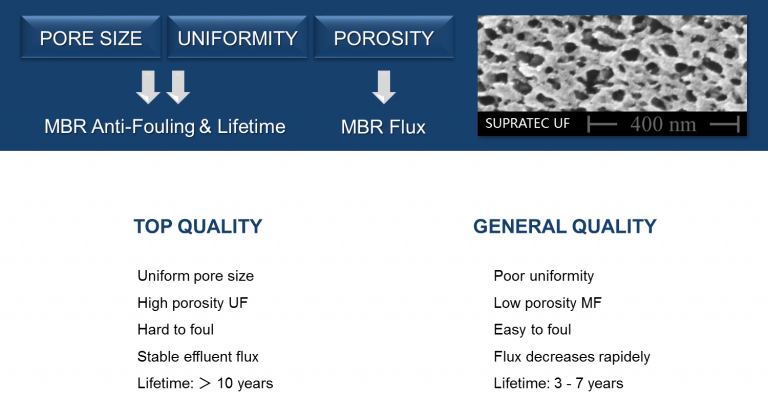

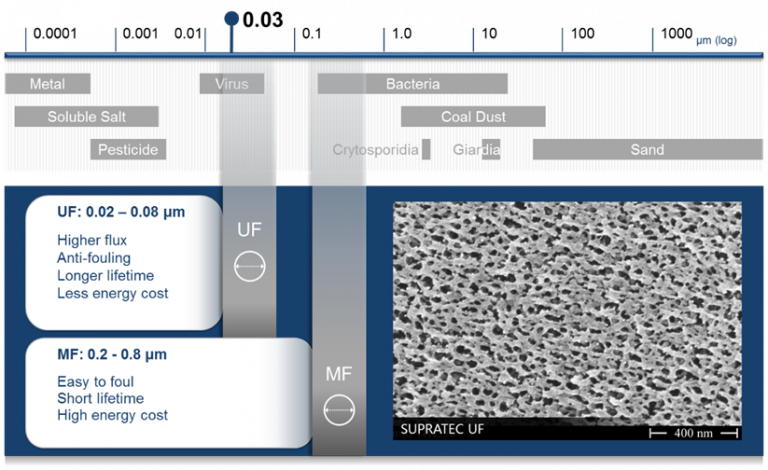

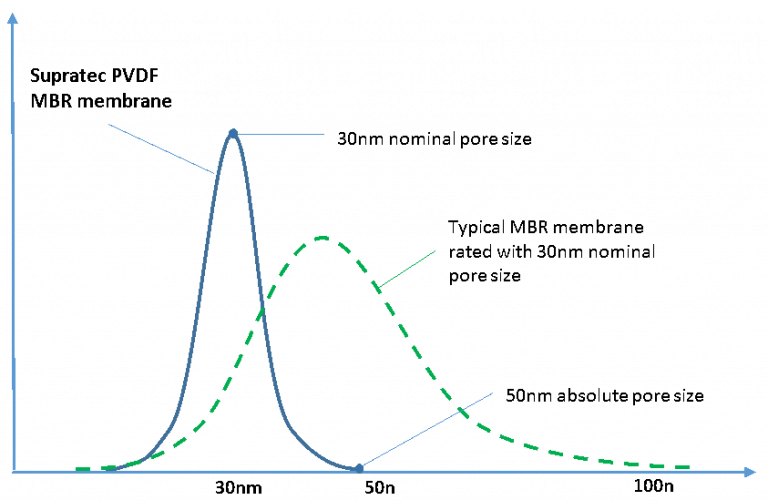

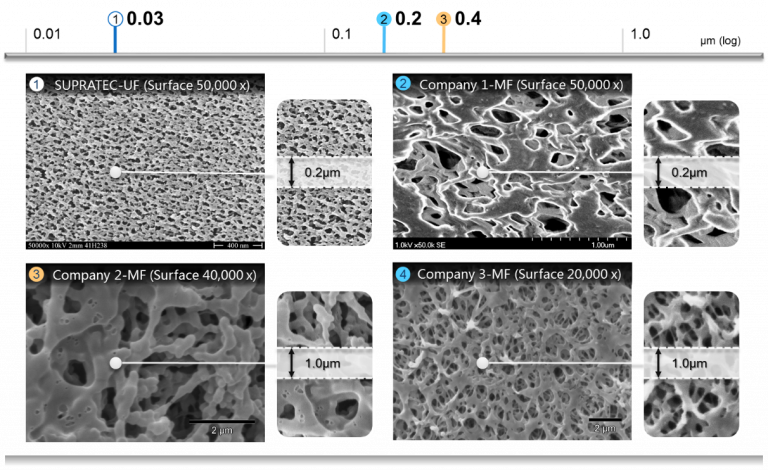

Compared to PES membranes, PVDF membranes are characterized by a better permeability and an advanced pore distribution as well as higher chemical and mechanical resistance.